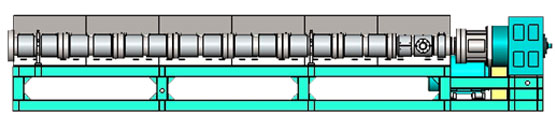

Composition:

Double screw extruder, net changer, single screw extruder, dynamic mixer, static mixer;

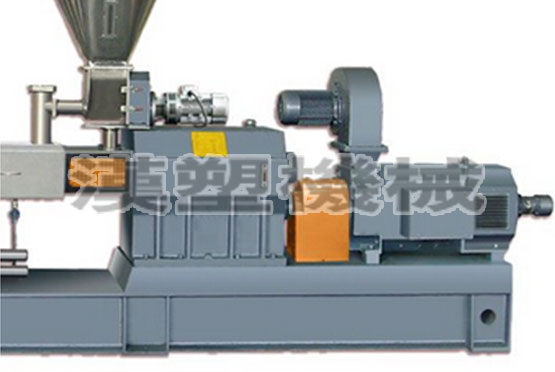

Double screw system

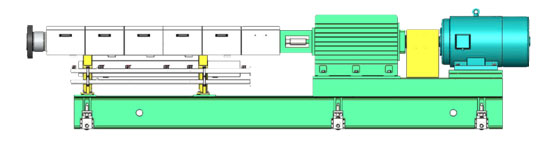

Single screw system

Creative using combined single screw section structure, has realized the single screw part can be back together to adjust according to the different requirements of products, can fully meet the stable production of XPS heat preservation, at the same time, effectively reduce the screw of the maintenance cost.

Model disctription:

(S - means the 1st stage is single screw extruder, D - means the 1st stage is double screw extruder)

Main extruder | Screw diameter(mm) | Driving motor(kw) | Extrusion capacity(kg/h) | Range of product density(mm) | Thickness range of product(mm) |

S90/120 | 90/120 | 45/37 | 150-200 | 28-36 | 20-50 |

S135/150 | 135/150 | 75/55 | 300-400 | 28-36 | 20-100 |

S170/200 | 170/200 | 200/90 | 400-600 | 28-36 | 20-100 |

D65/120 | 65/120 | 45/37 | 150-200 | 28-36 | 20-50 |

D75/150 | 75/200 | 110/90 | 300-400 | 28-36 | 20-120 |

D85/200 | 85/200 | 132/90 | 500-700 | 28-36 | 20-150 |

D95/250 | 95/250 | 160/132 | 700-1000 | 28-36 | 20-150 |

Notes: (1st stage screw Recommend to use double-screw)

Reasons of adopting double-screw :compared with single screw used for 1st stage of extruder, the double screw has more capacity, stable working.

CHINESE

CHINESE ENGLISH

ENGLISH